Product

All categories

High throughput tissue grinder

First, product use

1. Suitable for grinding preparation of soil agrochemical analysis samples;

2. Suitable for sample grinding in the early stage of pesticide residue detection;

3. Apply to the early grinding of samples for environmental toxicology detection;

4. Suitable for sample grinding in the early stage of soil composition detection;

5. Suitable for mass sample grinding and mixing.

Two, product characteristics

1. With national invention patent: passed CE certification;

2. Vertical oscillation: high stability, sample crushing and mixing thoroughly;

3. High efficiency: complete sample crushing within 2 minutes;

4. High flux: 2×15×15ml adapter, 2×8×50ml adapter can choose freely;

5. Large sample processing capacity: 2×300ml nylon tank (soil grinding, no metal pollution);

6. High safety: with safety door and safety lock;

7. No cross contamination: the sample tube is fully closed during the crushing process to avoid cross contamination;

8. Low noise: the operating sound of the instrument is less than 70dB, which will not interfere with other experiments or instruments.

Three, product principle

The vertical oscillation and high-frequency reciprocating motion of the oscillation system make the frozen sample in the grinding tube collide with the grinding ball, and the grinding shear force and impact force produced by the system make the tissue completely broken.

four. Technical parameters:

1. Host parameters:

1.1 Vertical oscillation, oscillation frequency: 500-1800 times /min;

1.2 Grinding time: 10-99 minutes, user can set;

1.3 Number of grinding tables: 2;

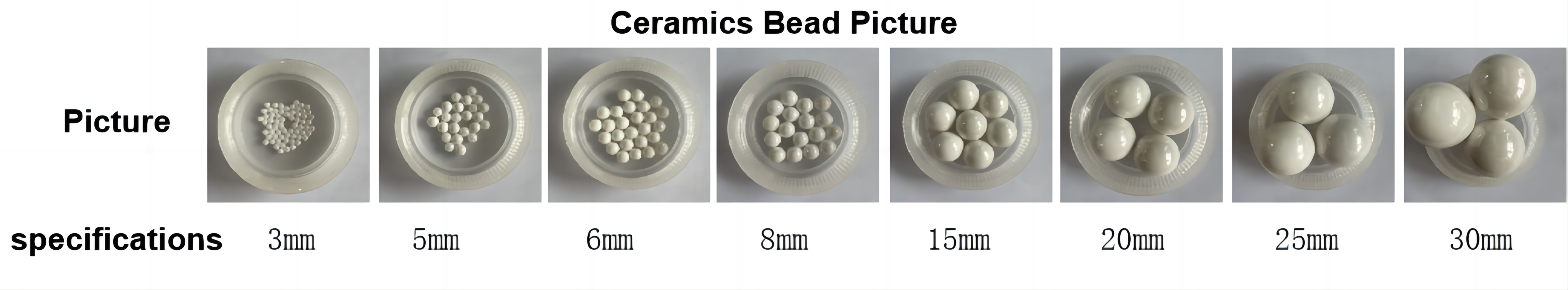

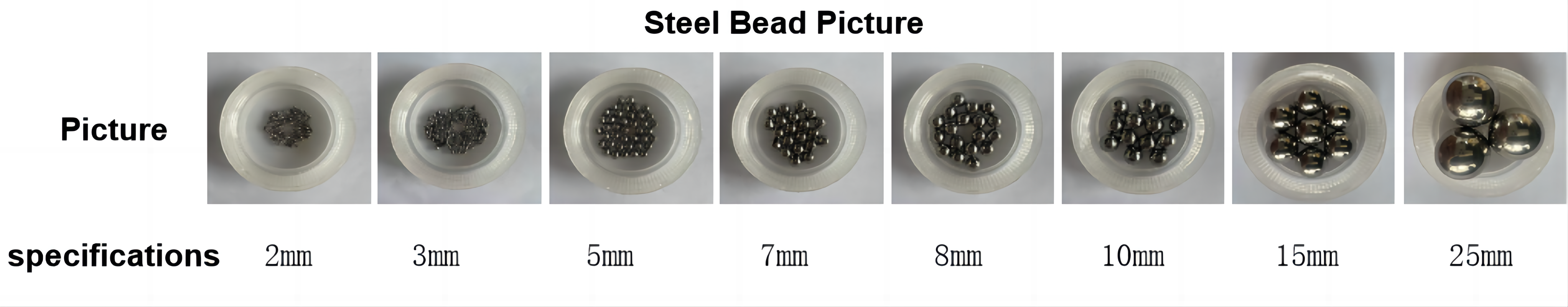

1.4 Grinding ball material: stainless steel, chromium steel, zirconia, tungsten carbide, quartz sand;

1.5 Ball diameter: 0.5-30mm;

1.6 Fixture travel 3.7cm(vertical);

1.7 Power: 400W;

1.8 Open door and power off function to ensure safety;

1.9 Power supply: 3-hole socket, 220-240V,50Hz;

1.10 Weight: 62kg;

1.11 Size: 38cm(W)×46cm(D)×50cm(H).

2. Adapter:

The adapter is used to hold the grinding tube containing the grinding ball and sample, and is positioned in the middle of the alloy fixture for use on the equipment. 8 hole (50ml), 15 hole (15ml) two specifications are available.

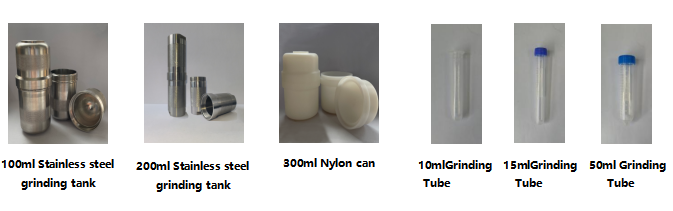

3. Grinding tube (can) :

The grinding tank is used to hold the grinding ball and sample, which is directly clipped to the main engine for use. 100ml stainless steel tank, 200ml stainless steel tank, 300ml nylon tank three specifications are available. The grinding tube holds the grinding ball and sample.

4. Grinding ball:

The grinding ball is used to help the sample break thoroughly. Various specifications are available according to requirements.

five. Product configuration:

1. One main machine;

2. A set of alloy fixture;

3. A set of grinding balls.

4. Adapter:

8-hole 50ml adapter 1 pair (standard);

15-hole 15ml adapter 1 pair (optional);

100ml Stainless Steel Grinding Tank 1 pair (optional);

200ml Stainless Steel Grinding tank 1 pair (optional);

300ml Nylon can 1 pair (optional);

Six, operation steps

1. Add the treated sample and grinding ball into the grinding tube successively;

2. Put the grinding tube loaded with sample into the adapter;

3. Freeze the adapter with sample in liquid nitrogen for a few minutes;

4. Put the frozen sample and adapter in the middle of the fixture and adjust the position;

5. Place the fixture on the sample table, position the positioning slot, tighten the vertical positioning knob, and return the lock safely;

6. Cover the safety door of the machine;

7. Set vibration frequency and vibration time;

8. Start the machine and execute the crushing process;

9. Wait until the machine stops vibrating and shuts down, open the safety door, and take out the sample;

10. Return the instrument.

Seven, precautions

1. The instrument should be placed in a dry and ventilated environment for use;

2. The sample is distributed symmetrically in the sample clip to ensure the balance of the sample clip;

3. Before closing the safety door, ensure that the fixture is completely fixed without loosening;

4. The oscillation frequency shall not exceed the maximum range of 1800 times /min;

5. When freezing samples, attention should be paid to prevent liquid nitrogen from spilling out and causing frostbite.