Product

All categories

Compost infrared biodegrader

Use of a product

1. Meet the testing requirements of GB/T19277.1-2011 standard;

2. Meet the testing requirements of ISO14855.1 standard;

3. Can be used for biodegradability research of bio-based materials and products;

4. Can be used for composting biodegradability detection;

5. It can be used in other simulated aerobic compost to determine its carbon dioxide release standard experiment;

Second, product characteristics

1. Fully meet the testing requirements of GB/T 19277.1 standard;

2. The design method of solid culture and open oxygen supply is adopted to simulate the strong aerobic environment;

3. High detection accuracy, online measurement of carbon dioxide release;

4. Double display of carbon dioxide, methane concentration and accumulation, which can be exported in the form of charts;

5. Wide detection range, the highest detection limit can reach 10000ppm;

6. Silent design, 9 independent controllable gas supply, sound less than 45db;

7. Air bath temperature control, temperature adjustment accuracy ±0.1℃;

8. Temperature control bin open cover sliding door design, easy to operate;

9. Cloud platform detection, online observation of data and curves;

Principle of three products

This experiment system simulates the process of biodegradation of bio-based materials under aerobic composting conditions. In the aerobic environment, microorganisms consume oxygen and produce carbon dioxide, water and other inorganic substances with bio-based materials as the carbon source. The generated carbon dioxide is monitored in real time by high-precision infrared sensors, and the real-time concentration of detected carbon dioxide is integrated with the flow rate and time to calculate the carbon dioxide release from the biodegradation of the sample. The biodegradation rate is the percentage of the carbon dioxide released by the sample biodegradation and its theoretical carbon dioxide release.

Four technical parameters

1. Working conditions:

1.1 Power supply voltage: AC 220V±10% 50Hz single-phase;

1.2 Working temperature: 15 ~ 30℃;

1.3 Relative humidity: ≤ 80%;

1.4 Durability of instrument operation: it can work continuously for a long time;

1.5 Machine power: 4KW;

1.6 Appearance size (L×W×H) : 1500mm×900mm×900mm;

1.7 Gross weight: 180KG;

2. Oxygen supply system:

2.1 Pre-decarbonization: Yes;

2.2 Air supply mode: continuous aeration oxygen supply, built-in air supply pump;

2.3 Air pump control: the air pump is divided into 9 channels, each channel is independently controlled;

2.4 Flow control mode: PLC control, flow can be automatically adjusted according to the set value;

2.5 Flow control accuracy: ±1%;

2.6 Flow collection method: electronic flowmeter real-time collection;

2.7 Flow collection range: 0.01-500ml /min;

2.8 With 9 electronic flowmeters to collect flow;

2.9 Flow control and flow collection operate independently;

3. Temperature control system:

3.1 Temperature control mode: air bath;

3.2 Set temperature range: room temperature -90 ℃, step by 0.1℃;

3.3 Temperature control accuracy :≤±0.1℃;

4. Reactor system:

4.1 Number of channels: ≥9;

4.2 Reactor volume :≥2000ml;

4.3 Reactor design: double-layer design;

4.4 Adding water: manually adding water;

4.5 Mixing method: manual mixing;

4.6 Material of reaction bottle: high borosilicate hard glass;

4.7 Gas supply mode: bottom gas supply;

5. Condensation dehumidification system:

5.1 System composition: manual condensation bottle and dehumidifier bottle;

5.2 Drainage Mode: Manual drainage;

5.3 Condensing temperature: room temperature;

5.4 Dehumidification method: the dehumidifier adopts double layer design;

5.5 Connection mode: Condensing bottle and dehumidifying bottle are designed in series;

6. Detection system:

6.1 Detection methods: carbon dioxide infrared probe to detect carbon dioxide, methane probe to detect methane;

6.2 Number of probes: 1 carbon dioxide infrared probe, 1 methane probe;

6.3 Display mode: synchronous dual display of carbon dioxide concentration and methane concentration;

6.4 Detection range: carbon dioxide 0-10000ppm, methane 0-5000ppm;

6.5 Resolution: 1ppm;

6.6 Data collection period: 5min;

6.7 Probe dehumidification protection system: Yes;

6.8 Temperament analyzer: can be used in combination;

6.9 Anaerobic biodegradation experiment: can be done;

7. Software system:

7.1 Software control system with independent intellectual property rights;

7.2 Software data collection, can generate real-time data curve;

7.3 Bearer system: Professional operating system such as win7/8/10;

7.4 Data storage: It can be stored in real time in the experiment;

7.5 With a cloud platform, data can be accessed remotely;

7.6 Operation durability: can work continuously for more than 6 months;

Five instrument configuration requirements

|

Serial number |

name |

quantity |

unit |

remark |

|

1 |

Host machine |

1 |

Taiwan |

|

|

2 |

Reaction flask |

9 |

a |

|

|

3 |

Decarbonizing plant |

9 |

Set of |

|

|

4 |

Condensing bottle |

9 |

a |

|

|

5 |

Dehumidifier bottle |

9 |

a |

|

|

6 |

Connecting hose |

1 |

Set of |

|

|

7 |

software |

1 |

Set of |

|

|

8 |

Random file |

1 |

Set of |

|

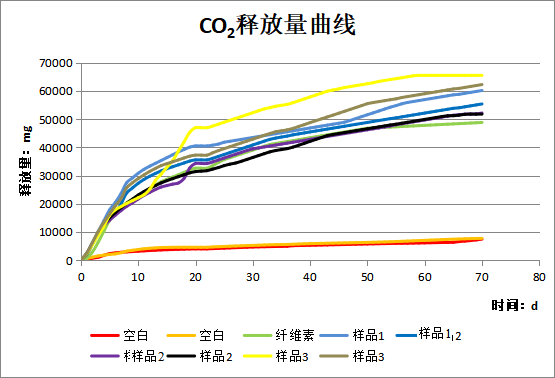

Examples of experiments

This is the experimental result of testing the biodegradability of a sample by using the M9000 compost infrared biodegrader and referring to the method standard GB/T19277.1-2011. The test period was 70 days. As can be seen from Figure 1, the degradation rate of cellulose reached 81.88% within 45 days. Within 70 days, the degradation rate of cellulose reached 98.18%. At this time, the growth of each experimental group basically ended, and the curve was smooth. The experimental design was shown in the following table:

Table 1 Experimental design

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

|

Inoculation |

300g | 300g | 300g | 300g | 300g | 300g | 300g | 300g | 300g |

|

Cellulose |

30g | ||||||||

|

Sample 1 |

30g | 30g | |||||||

|

Sample 2 |

30g | 30g | |||||||

|

Sample 3 |

30g | 30g |

|

|

Figure 1 CO2 emission curve |